about us

News Center

Your current location:Home - About us - News center

Connectors for electronic equipment – Product requirements –

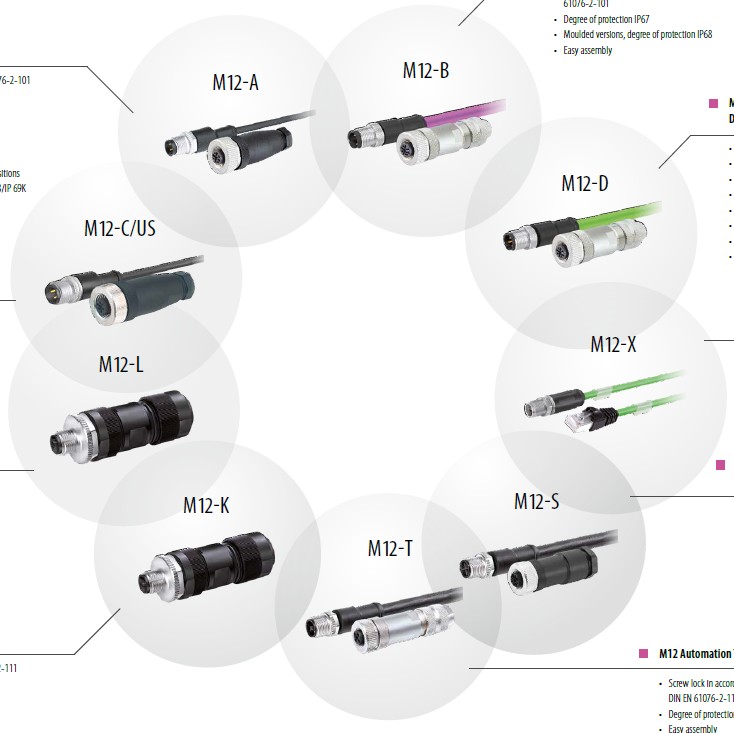

Part 2-101: Circular connectors – Detail specification for M12 connectors with screw-locking

CONNECTORS FOR ELECTRONIC EQUIPMENT – PRODUCT REQUIREMENTS –

Part 2-101: Circular connectors –

Detail specification for M12 connectors with screw-locking

indispensable for the correct application of this publication.

ernational Standard IEC 61076-2-101 has been prepared by sub-committee 48B: Connectors, of Technical Committee : Electromechanical components and mechanical structures for electronic equipment.

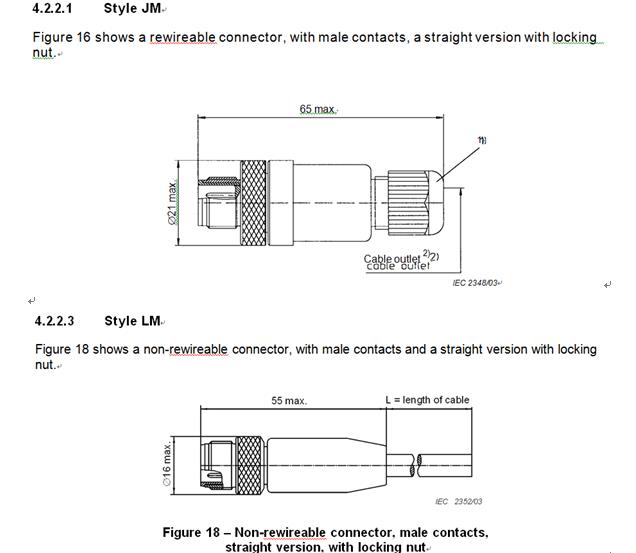

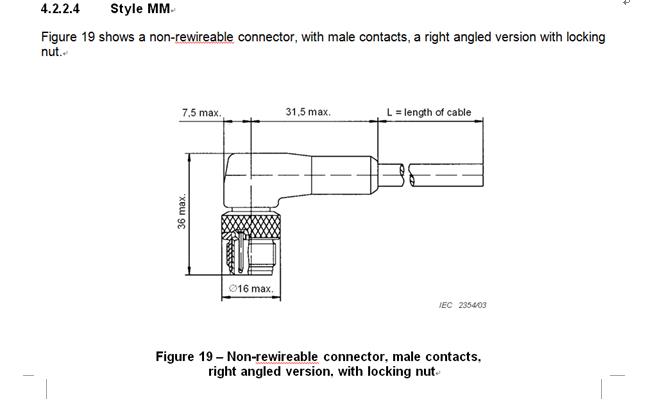

This part of IEC 61076 describes M12 circular connectors typically used for industrial process measurement and control. These connectors consist of fixed and free connectors either rewireable or non-rewireable, with screw-locking. The connectors with glass to metal seal are fixed connectors only which consist of fixed glass to metal sealed styles with rewireable male contacts and are intermateable with corresponding free connectors according to this International Standard. Male connectors have round contacts Æ 0,6 mm, Æ 0,76 mm, Æ 0,8 mm and Æ 1,0 mm.

The different codings prevent the mating of these coded male or female connectors to any other interfaces and cross-mating between the different codings.

NOTE M12 is the dimension of the thread of the screw-locking mechanism of these circular connectors.

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

IEC 60050-581: 2008, International Electrotechnical Vocabulary (IEV) –

IEC 60068-1,Environmental testing – Part 1: General and guidance

IEC 60068-2-60,Environmentaltesting– Part 2: Tests –Test Ke: Flowing mixed gas corrosion test

IEC 60352 (all parts),Solderless connections

IEC

60423:2007,Conduit systems for cable

management – Outside diameters of conduits for electrical installations and

threads for conduits and fittings

IEC 60512 (all parts),Connectors for electronic equipment – Tests and measurements

IEC 60512-1-100,Connectors for electronic equipment – Tests and measurements – Part 1- 100: General – Applicable publications

IEC 60529:1989,Degrees of protection provided by enclosures (IP code)

IEC 60664-1,Insulation coordination for equipment within low-voltage systems – Part 1: Principles, requirements and tests

IEC 60998-2-1,Connectingdevices forlow-voltage circuitsforhouseholdand similarpurposes– Part 2-1: Particular requirements for connecting devices as separate entities with screw-type clamping units

IEC 60999 (all parts), Connectingdevices – Electrical copper conductors – Safety requirements for screw-type and screwless-type clamping units

IEC 61076-1:2006,Connectors for electronic equipment – Product requirements – Part 1: Generic specification

IEC 61984,Connectors – Safety requirements and tests

ISO 1302: Technical drawings – Methods of indicating surface texture

For the purposes of this document, terms and definitions from IEC 60050-581 as well as the following apply.

mounting orientation

circular mounting position of the connector in relation to the polarization of the mating interface

NOTE Where the free connector has an angled cable entry (as opposed to an in-line cable entry), the angle between the cable entry direction and the polarization keyway should be specified.

glass to metal seal

a form of construction whereby the connector contacts are housed in a glass insert which is inside a metal connector shell so as to form a connector with a hermetic seal which may be used to isolate differing environments

matched glass to metal seal

a form of construction whereby the thermal expansion characteristics of the glass, the metallic contacts, and the connector shell are similar and the seal between the glass and the metal is formed by a chemical bond

compression glass to metal seal

a form of construction whereby due to the its higher coefficient of expansion the shell contracts around the glass during the solidification phase of manufacture applying a compression force to the glass insert so as to form a seal

The contact terminations shall be of the following types: screw, crimp, insulation piercing, insulation displacement, press-in or solder. For the male connectors havinga glass to metal seal the recommended contact terminations are crimp, eyelet, solder, PCB and rounded.

NOTE 1 eyelet – the termination end is flattened and pierced with a hole to provide both mechanical retention of the wire as well as solder attachment.

NOTE 3 PCB – termination spills suitable for insertion into printed circuits.

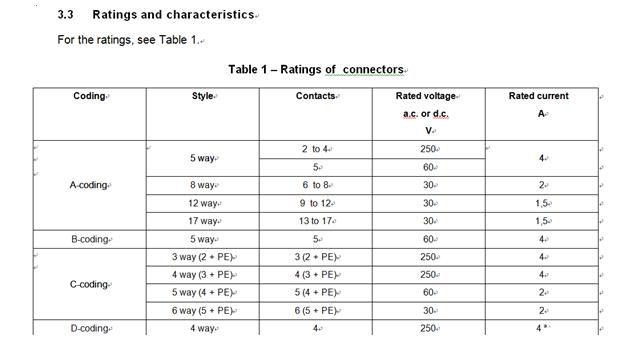

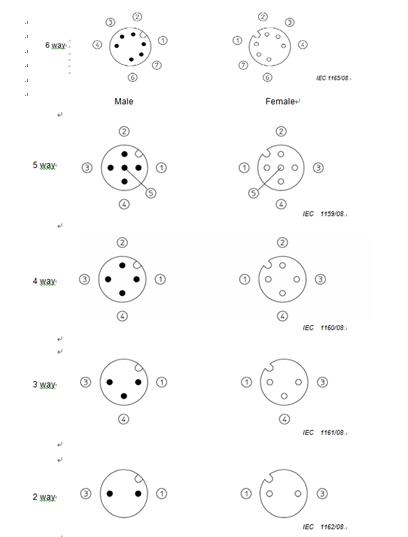

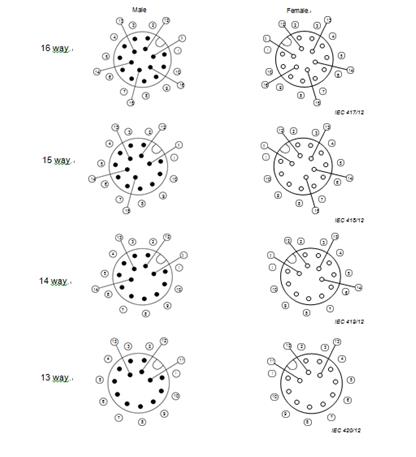

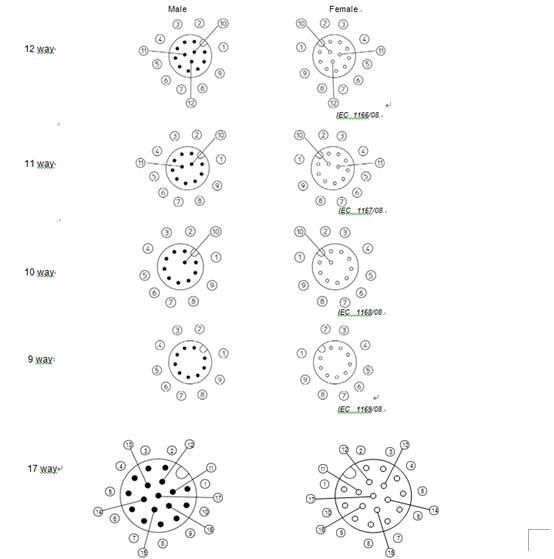

A-coding 2 to 17 contacts

B-coding 5 contacts

C-coding 3 to 6 contacts

D-coding 4 contacts

P-coding 5 contacts (4+PE)