about us

News Center

Your current location:Home - About us - News center

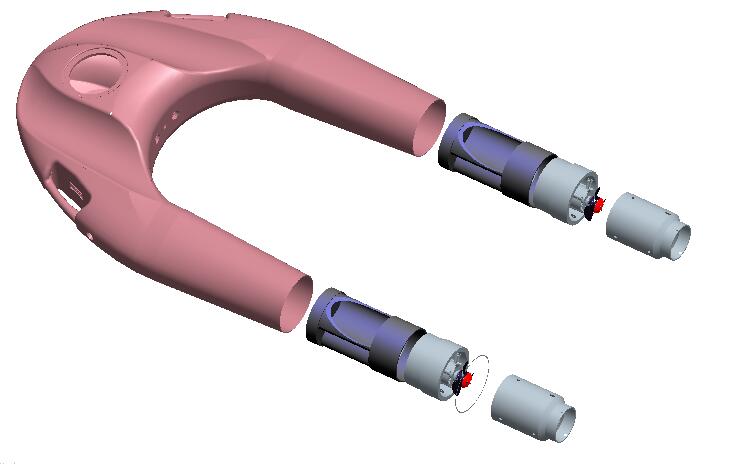

Waterproof

structure design services, we designed the product waterproof structure can be

said to be completely no problem, but for the reasons of poor waterproof

generally plastic deformation, waterproof surface is not in a line, O-ring

preloading is too loose or too tight, structural stiffness is not enough,

uneven screw distribution or slippery teeth, etc. The malpractice of plastic

deformation is obvious and easy to occur. There are many ways to improve it,

such as improving the rubber mouth, transporting water, strengthening the bone,

increasing the slope of demoulding, etc. For some products, the cause of

deformation may also be caused by the shape limitation leading to the need for

curved surface parting of front and rear shells, or by the large change of the

wall thickness of plastic parts caused by too small internal space.

Some products are

prone to deformation due to the influence of residual stress of plastic beer

plastics, and need to be waterproof. In order to reduce deformation, in

addition to strengthening bone, increasing demoulding inclination and

increasing ejection position, fixture positioning and shaping should be done

when the product beer plastics come out when necessary, and natural cooling in

warm water to reduce residual stress. In some products, transparent mirrors

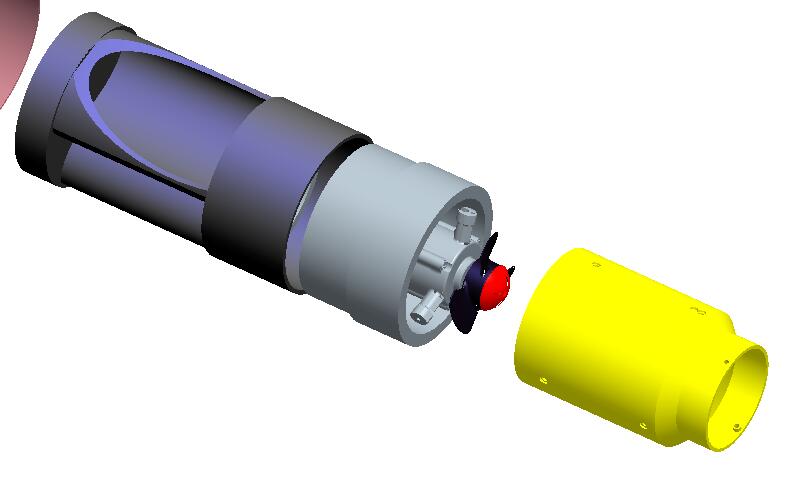

should also be and after. The shell is waterproof through O-ring. It is

suggested that the LCD and PCB should be wrapped in a metal cover of 0.15, and

the screw should be fixed on the lens, so that the plastic beer plastic

deformation will be smaller.

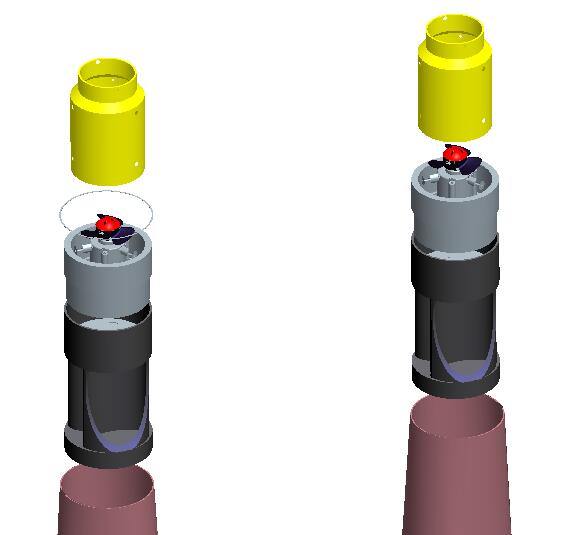

In the process of

design, orange industrial design has accumulated quite a wealth of waterproof

structure treatment methods. For some products with waterproof requirements, in

the early stage of ID design, we will avoid the bad waterproof caused by the

shape and structure, and avoid the O-ring to make irregular curved surface.

Generally speaking, if the waterproof line is not coherent after the upper and

lower cover, it is not on one surface. Water effect is mostly not good, even to

the shape of ultrasound treatment effect will not be good, should be avoided as

far as possible, so there are certain requirements for designers, they need to

know certain structural knowledge, in the early stage of ID modelling design,

to avoid such modelling.