about us

News Center

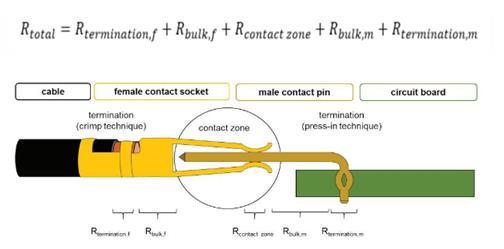

Your current location:Home - About us - News centerContact resistivity: The resistance that appears between conductors. It is the total resistance composed of a shrinkage resistor (concentration resistor) and a film resistor.

Solids are rough and uneven. Contact has divided the surface into different grades of roughness, and contact resistance is based on micron- or nano-scale contact areas.

Microscopically, the surface of the contact body after electroplating still has 5-10 micrometers of protrusions. Therefore, after the contact body is inserted, not the entire contact surface is completely in contact, but scattered at some points, so the actual contact surface is inevitably smaller than the theory. Contact surfaces. The actual contact surface is divided into two parts: one is the direct contact between the metal and the metal; the other is the part that contacts the film after the interface is contaminated by the interface.

When the current passes through the contact point, the current line shrinks (or concentrates) and increases the resistance. This increased resistance is the shrinkage resistance (concentration resistance).

Contact with the surface film and other contaminants will also form a certain resistance, which is the film resistance. The presence of the film can also change the hardness of the contact surface and affect the contact resistance by changing the deformation of the contact surface. If the film is formed by ion diffusion, the film resistance will increase. The conductive coating formed by electroplating has a lower hardness than the hardness of the substrate, higher conductivity, stronger corrosion resistance, and smoother resistance. The film resistance is also called the interface resistance.

Membrane resistance is a complex process that can be broken down, and the resistance drops rapidly after breakdown, and is "repaired" after the thermal effect of the current. The magnitude of the current passing through the film layer is different, and the difference in resistance is also large, and a strong current will punch through the film layer and reduce the resistance of the film layer.

In addition to the above two resistance components, when measuring the contact resistance by the tool, the resistance value also includes the resistance of the contact and the wire in the measuring device.

Summary: Contact resistance is not a constant value, it is easily affected by other external factors, so it will be calibrated within a certain range in the standard, and it will be qualified if it does not exceed the standard range. For example, in GJB 101A-97, the 1.0mmr copper alloy contact body should have a contact resistance of ≤5mΩ before the life test and ≤15m after the life test.