The connector has not been put into the supply limited device before, because in addition to the TEMOLEX (American Amphenol), there are many Japanese connector manufacturers, such as JSTJAE Sumitomo, and so on. Moreover, domestic connector suppliers are also good, not as small as chips.

The acquisition board and control board in BMS usually use low-voltage connectors. Every time I choose a type, I have a headache, because I can't choose a product that meets all kinds of needs in my heart. Am I asking too much? Now let's take a look at it for me.

Demand 1: Error prevention

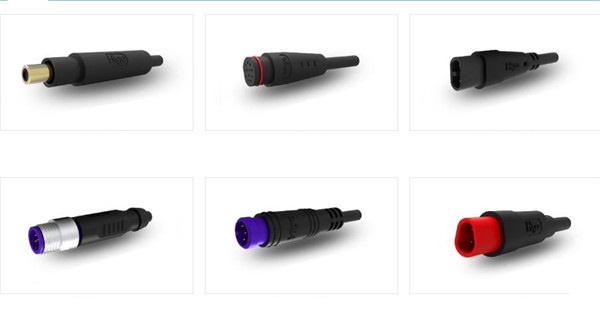

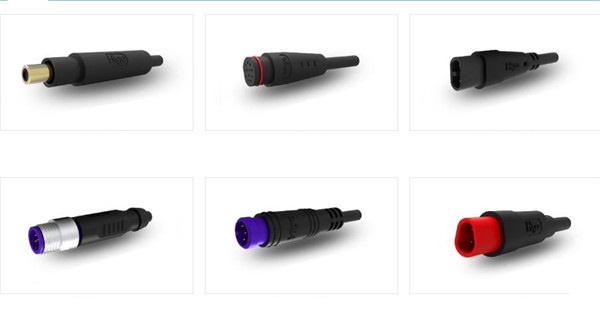

Error proof is the first requirement. Especially in the centralized acquisition board, there are many sampling connectors. In order to avoid artificial insertion errors, it is necessary to do anti-foolish design. Need to satisfy two kinds of anti-daze at the same time: one is structural anti-daze, the other is color anti-daze.

For example, choose different PIN number of connectors to do structural anti-stall; or the same PIN number to do the internal structure of the card slot anti-stall.

The main purpose of color anti-dull is to facilitate production and processing, including PCBA manufacturing and PACK assembly process, reduce complaints from the production line and possible problems.

Needs 2: Locks

Connectors should have locking structure, on the one hand, to resist external mechanical load, but also give users a sense of hearing or hand information, let people know that the connectors have been paired or separated. Here is the tuck slot, some manufacturers connector, after the crimp wiring harness, the insertion force is very big, you have to use the whole body strength to pull down, make the hand pain; the reason is that the length of travel and other control is not good, cause the feel is very poor.

Needs 3: Long and short PIN needles

This is the PIN pin of the finger end connector. It is necessary to have some PIN needles longer. Similar to the charging gun interface and the socket, some PIN pins need to be touched first; this requirement is applied to make the GND or the power cord contact first, then touch the other signal lines.

For example, in the sampling interface of AFE, V-and V+are connected to AFE first, and other sampling lines are contacted later. In this way, AFE first establishes a stable power supply system to reduce the damage caused by different potential. This requirement is very practical and important.

Requirement 4: Flame retardant grade V0

Connector flame retardant requirements, in order to consider the safety performance, connectors need to reach UL94-V0 level, manufacturers are gradually moving in this direction, but generally speaking, there are not many optional connectors; some connectors, board end to meet V0, but the line end is HB, in the selection to ensure that both are V0.

Flame retardants are usually added to plastics to improve their flame retardant properties and prevent or delay their combustion. The following picture shows the flame retardant properties of commonly used plastics (the picture is somewhat blurred, but can not be found clearly at present).

Demand 5: Waterproof or not

There is no uniform requirement for waterproofing of connectors on BMS. Generally, BMS is installed in battery PACK, while PACK generally requires IP67, so BMS generally does not need waterproofing, and connectors are non-waterproofing connectors. The main disadvantage of waterproof connector is size and cost, especially the BOM cost is getting lower and lower, so it is difficult to choose waterproof connector.

Conclusion:

The above requirements are relatively rough, and no specific electrical parameters have been developed; when these requirements work together, it is very difficult to find the appropriate model, so the final discount will be used; later, I intend to introduce the reliability of connectors and other content, which need to be well prepared. All the above are for reference only.