about us

News Center

Your current location:Home - About us - News center

Industrial medical face mask connector vent valve N95

respirator is one of nine kinds of particle respirators certified by NIOSH

(National Institute for occupational safety and health). "N" means

not resistant to oil. "95" means that the particle concentration in

the mask is more than 95% lower than that outside the mask when exposed to a

specified number of special test particles. 95% is not the average, but the

minimum. N95 is not a specific product name. As long as the product meets N95

standard and passes NIOSH review, it can be called "N95 mask". The degree

of protection is N95, which means that under the test conditions specified in

NIOSH standard, the filtering efficiency of the filter material of the mask for

non oily particles (such as dust, acid mist, paint mist, microorganism, etc.)

reaches 95%.

Mask

material

Non-woven

fabrics /

It

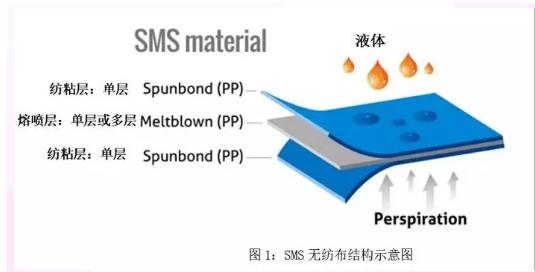

is generally said that the mask is made of non-woven fabric. Compared with

textile fabric, non-woven fabric is made of directional or random fibers. As

for the mask, its raw materials are all polypropylene (PP for short). The mask

for medical use is generally multi-layer structure, generally referred to as

SMS structure. See the figure below for the schematic diagram.

And

we often say that several layers of masks, in the national standard of masks GB

/ T 32610 does not stipulate that if it is a mask for medical use, it should be

at least three layers, that is, SMS (two layers of S and one layer of M). At

present, the highest number of layers in China is five layers, that is smmms

(two layers of S and three layers of m). It is not difficult to make a mask, but

it is more difficult to make smmms cloth. The price of an imported non-woven

fabric equipment is more than 100 million yuan

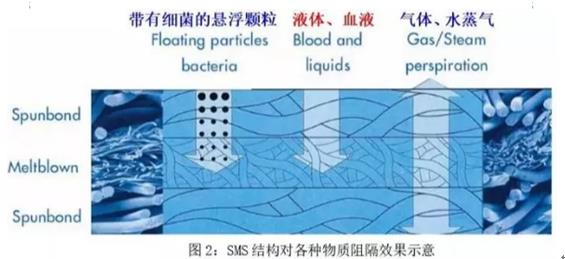

In

this case, s represents spunbond, whose fiber diameter is relatively thick,

about 20 microns (μ m). The main function of two layers of s spunbond is to

support the entire non-woven fabric structure, which has little effect on

barrier.

The

most important part of the mask is the barrier layer or melt blown layer m

(meltblown). The fiber diameter of the melt blown layer is relatively small,

about 2 microns (μ m), so it is only one tenth of the diameter of the spunbond

layer, which is very important to prevent bacteria and blood from penetrating.