about us

News Center

Your current location:Home - About us - News center

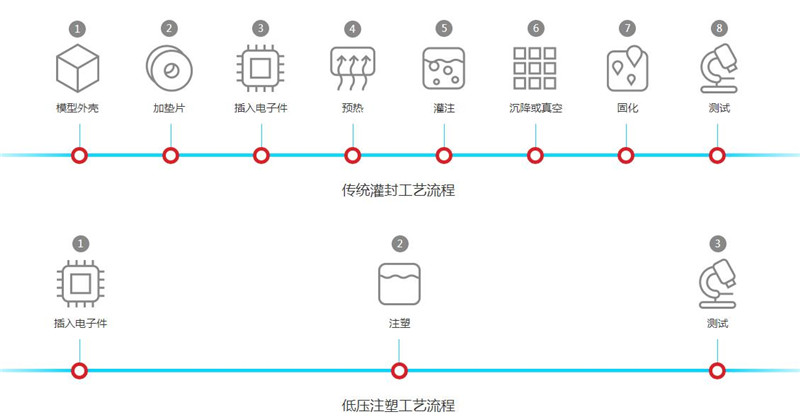

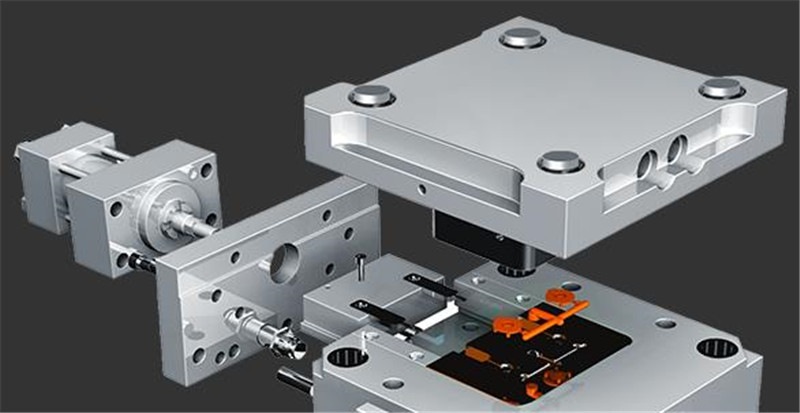

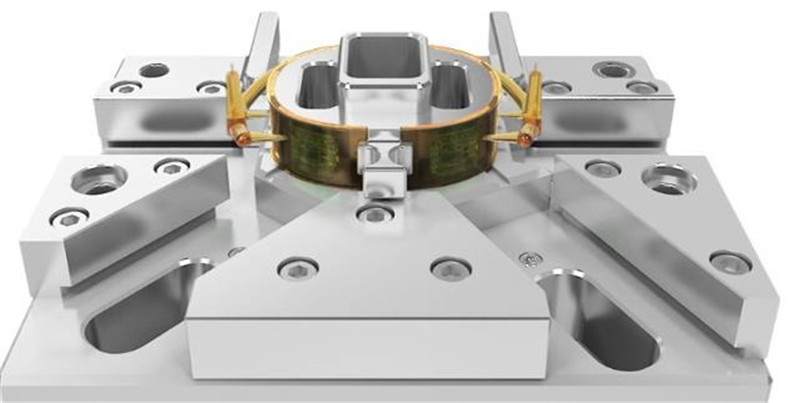

Low

pressure nylon plastic injection molding is one of the production processes of

circular connectors for electrical equipment. It has low cost, high waterproof

reliability, high temperature resistance and chemical pollution resistance. It

can be used around the equipment for a long time. This molding process is:

components are installed into the mold, mold is closed, preheated, injected,

settled or vacuumed, heated and solidified, demoulded, and products are

produced

In

this process, the factors that affect the accuracy of industrial electrical

equipment are heating temperature, time, pressure, purity and viscosity of

nylon particles, temperature control drop of equipment, these parameters, which

can be mastered in the production process to make a good product. It can be

effectively bonded with any line material, achieving the highest level of

waterproof and airtight performance, and the highest temperature steaming Air

tight standard. It is the best production process to produce industrial

electrical circular connector to achieve high-performance waterproof, the most

concise production process, so that your products are competitive in the

industry.

Low pressure injection molding production process : Download Industrial low pressure injection production process details PDF file.