about us

News Center

Your current location:Home - About us - News center

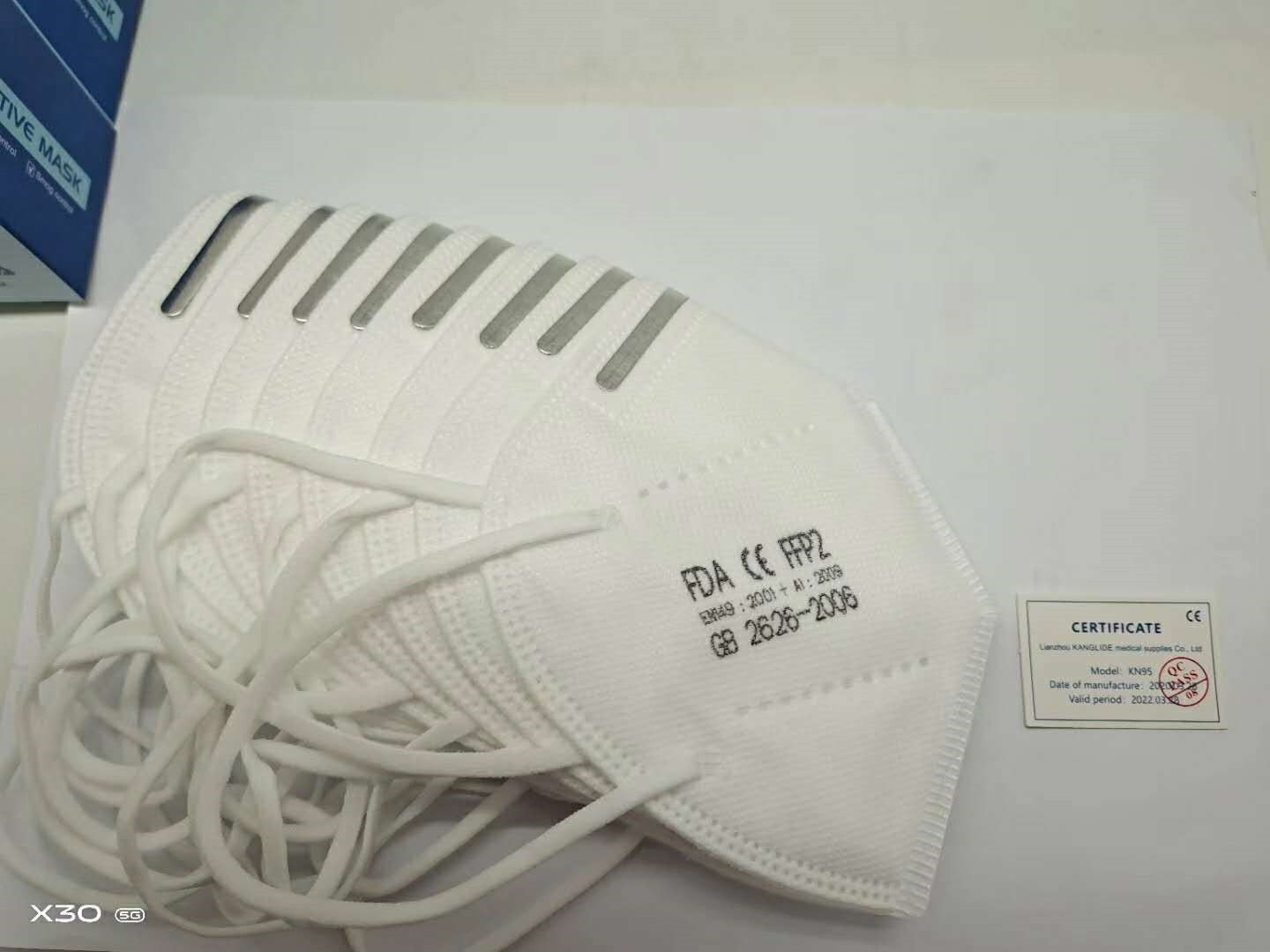

Medical equipment masks are divided into: 1

for civil use, 2 for medical use and 3 for medical surgery

1 for civil use: the first type is disposable

mask without disinfection, and the anti-virus rate is 0%

The second type of sterilized mask is called

disposable sterile mask, with an anti-virus rate of 45%

The third kind of N95 has 95% anti-virus rate

2 medical class: the anti-virus rate of

disposable medical mask is 85% or 90%, N90 or Kn90 or kf94

3. Medical surgery: the anti-virus rate of

medical surgery is 95%. Medical surgical mask is a recognized product for cross

infection prevention in operating room.

If you need it , please contact E-mail : sales01@ximeconn.com

We can deliver at any time on express .

The new EU regulation (EU) 2016 / 425 has

been implemented. Respirators belong to the three categories of products

"substances and mixtures endangering health". They must apply for

approval according to module B + module C / D, similar to Section A / B,

Chapter 11, EC type inspection, Chapter 10, Directive 89 / 686 / EEC of the old

regulation.

With the growing awareness of the hazards of

PM2.5, the protection of PM2.5 is also increasing, and the use of masks is

increasing. The state has also updated gb2626-2016 respiratory protective

equipment. It's a very big business opportunity for businesses. Here's a brief

talk about the requirements of major countries in the world for mask

certification and testing. Gb2626-2006 according to the leakage rate of the

mask and the filtering efficiency of the mask itself, the mask is divided into

three grades: 90 (Kn90, kp90), 95 (kn95, kp95) and 100 (kn100, kp100). This

standard is closer to the international standard, such as the European Union

standard EN 149, NIOSH certified mask in the United States, as 1716 in

Australia and js-t-8151 in Japan

Products sold in the EU market must obtain CE

certification. From 2019, the new regulation (EU) 2016 / 425 will be enforced.

All masks exported to the EU must obtain CE certification under the

requirements of the new regulation. EU standards for common respiratory

products are as follows:

BS EN 149: 2001 filtering half masks to

protect against particles

BS EN 136: 1998 full face masks - class 1, 2,

or3 full face masks - class 1, 2 or 3.

BS EN 140: 1999 half / quarter masks

BS EN 14387: 2006 gas filters & combined

filters

BS EN 143: 2000 particle filters

NIOSH classifies its certified particulate

respirators into 9 categories according to Department of health and human

services (HHS) Regulation 42 CFR Part 84. The specific certification is

operated by npptl (National Personal Protective Technology Laboratory) under

NIOSH.

According to the filtering characteristics of

the middle filter screen of the mask, it can be divided into the following

three types:

Grade 100: the minimum filtration efficiency

is 99.97%.

Grade 99: indicates that the minimum

filtration efficiency is 99%.

Grade 95: indicates a minimum filtration

efficiency of 95%.

According to the minimum filtering efficiency

of the filter screen material, the mask can be divided into the following three

grades:

N series: n stands for not resistant to oil,

which can be used to protect non oily suspension particles.

P Series: P stands for oil proof, which can

be used to protect non oil and oily suspended particles.

R Series: R stands for resistant to oil,

which can be used to protect non oily and oily suspension particles.

N95 respirator is one of nine kinds of

particle respirators certified by NIOSH (National Institute of occupational

safety and health). "N" means the particles that are not suitable for

oil (the oil smoke produced by cooking is the oil particles, while the droplets

produced by people's talking or coughing are not oil particles); "95"

means that under the detection conditions specified in NIOSH standard, the

filtration efficiency reaches 95%. N95 is not a specific product name. As long

as the product meets the N95 standard and passes the NIOSH review, it can be

called "N95 mask".

As / NZS 1716:2012 is the respiratory

protection device standard in Australia and New Zealand. Manufacturing

processes and tests must be in accordance with this specification. This

standard specifies the procedures and materials that must be used in the

manufacturing process of particle respirators, as well as the determined test

and performance results to ensure their use safety.

When the safety of life depends on PPE

products, benchmark certification will provide you with real confidence. As a

testing and certification agency, we believe that we can certify and test our

laboratory products according to the industry recognized standards. From safety

glasses to complex respiratory and fire-fighting equipment, we help

manufacturers prove that safety is essential and that products have been proven

to meet agreed high standards.