Screw torque control method of M12 waterproof circular connector: the thread connection and its influencing factors are analyzed. Combined with the production practice, when the output torque of the four axle front and rear axle U-bolt tightening machine reaches the target value (the torque value is displayed on the main monitoring operation display screen), the torque of the nut can not meet the requirements of the process specification The difference between the dynamic torque and the static torque is tested and analyzed. The torque control value is obtained by statistical method. The concept of dynamic torque and static torque is introduced in the torque control process to establish the torque control method, which is applied to the product quality control process.

Threaded connection connects two parts by bolt axial pre tightening force, which is a common connection mode in mechanical products. Bolt axial pre tightening force has a direct impact on connection strength, thread pair anti loosening and sealing between connected parts. Stable and appropriate axial preload is the premise of reliable connection. In practical work, it is not convenient to directly measure the bolt axial clamping force, so it is generally necessary to control the bolt torque to obtain the appropriate axial clamping force.

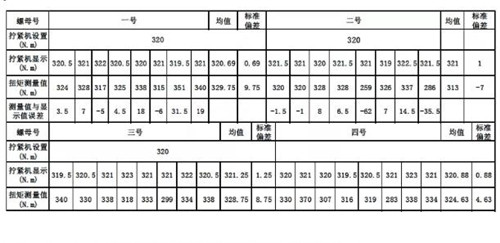

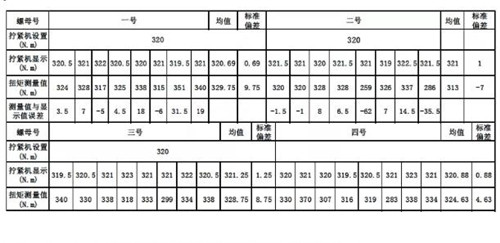

During the assembly process of the front and rear axle and leaf spring of the engineering vehicle, the pre tightening of the riding bolt and nut is carried out, Under the condition of confirming that the connecting parts, thread pairs and operation methods are in a stable state, the electric tightening machine is used to tighten the nut to be measured, and then the torque value is detected by the digital display torque wrench. It is found that the torque value is inconsistent and can not meet the requirements of the process specification (as shown in Table 1). This paper analyzes the problem and puts forward the method to solve the problem.

Preconditions: 1. Process specified torque: 200N. M ~ 250N. M; 2. Setting torque of tightening machine: 250N. M

1、 Analysis of factors affecting torque

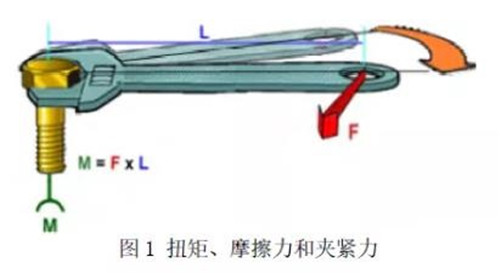

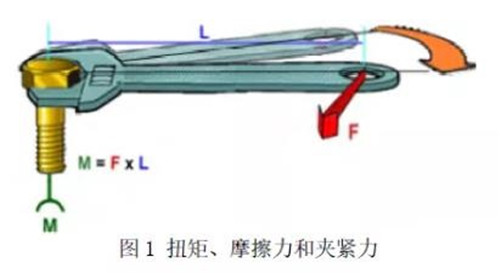

The relationship among torque, friction and clamping force is shown in Figure 1: torque (m) = force (f) × arm (L)

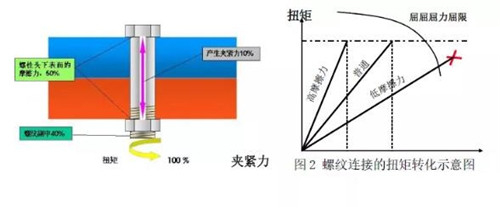

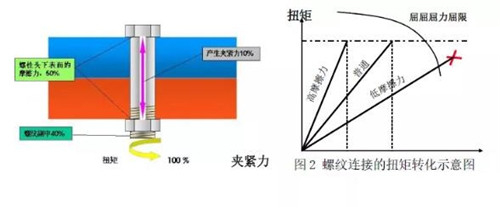

According to the principle of torque and tightening technology, the relationship among torque, friction and clamping force is shown in Fig. 2. When the bolt is stretched during tightening, it will produce clamping force on the connector. However, in the assembly process, 90% of the torque is consumed by friction, and only 10% of the torque is converted into clamping force. But in the actual assembly process, the clamping force can not be measured, it is difficult to detect, we can measure the torque.

1. The influence of friction

Through calculation: the change of friction force will lead to 40% change of clamping force in the connector. From the analysis of torque control method, the axial pre tightening force F of bolt is directly proportional to the tightening torque T applied during tightening. Expressed by T = KF, K is the torque coefficient, and its value is mainly determined by the friction resistance between contact surfaces and between thread teeth. In general, the K value is about 0.2-0.4, and sometimes it is between 0.1 and 0.5. Therefore, the change of friction resistance has great influence on the torque. That is to say, when two connectors with different friction resistance are tightened with the same set torque value, the bolt torque obtained is greatly different, which can be up to twice. With different nut States, the friction force is different, and the torque changes accordingly.

2. Connection mode

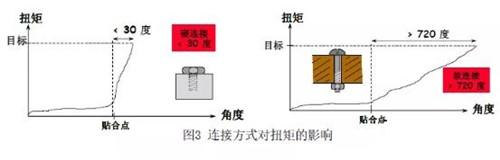

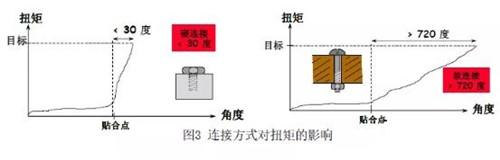

The connection mode is divided into hard connection, neutral connection and soft connection. According to QC / t518-2007 automotive threaded fasteners tightening torque specification requirements, grade 8.8 M14 × 1.5 The torque of the bolt is 146n. M ~ 206n. M. the static torque is 156n. M ~ 248n. M for hard connection, 141n. M ~ 247n. M for neutral connection and 108n. M ~ 262n. M for soft connection. The influence torque is ± 27.2%. In the process of tightening, the greater the deformation of the connector and the connected part in the axial direction of the bolt, the more "soft" the connection is; on the contrary, the more "hard" the tightening angle of the hard connection is less than 30 ° and the tightening angle of the soft connection is greater than 720 ° in the actual bending, but most of the connections are neutral connections, and the tightening angle is between 30 ° and 720 °. The influence of connection mode on torque is shown in Fig. 3

3、 Torque control

1. The correct evaluation of static torque value is to collect 100 actual torque measurement values, and then calculate the standard deviation s with the help of statistical analysis method. According to the actual assembly situation, ± 2S or ± 3S is taken as the upper and lower bending limit of the control range, which is used to inspect and evaluate the tightening effect of bolt connection, and the measured static torque value must be within the set upper and lower bending limit. However, in the process of formulating the static torque value, due to the limitation of personnel and time, it is impossible for each fastening bolt to be measured 100 times. In order to obtain the correct torque and quickly and conveniently formulate the static torque value, the following empirical formula can be used (T: middle value in the figure; t: the middle value in the figure; t: the middle value in the figure);

a: The static check intermediate value so and static tolerance B are calculated, and the static torque value is determined according to the requirements of tolerance change ≤ 35% and median change ≤ 15% in the general global static torque specification release and update process (NOA No. ggas-345).

2. Draw up the comparison table of dynamic torque and static torque for the control range and inspection of actual production, as shown in Table 3.

3. Formulate the static torque test specification.

4、 Conclusion

The tightening of leaf spring riding bolt is one of the key points of automobile assembly torque control. The qualified torque control is very important to the assembly quality, but there are many factors affecting the torque. In the actual production, especially in the process of mass production, torque control is a complex work. Through the analysis of the influence of torque, the relationship between dynamic torque and static torque is found, and it is applied to the company for implementation Quality control QCOS, solve the actual production of bolt tightening torque control method, improve the stability of product quality.